Control temperature rise and Reduce heat generation

发布时间 : 2026-01-17 浏览次数 : 次Generally, when we talk about the issue of thermal deformation in CNC cutting machines, many people tend to focus on the dimensional deformation of the cutting material itself. However, as a thermal cutting processing device, the CNC cutting machine itself may also experience structural deformation due to temperature changes during frequent use. Although CNC cutting machines, as manufacturing equipment, will adopt a series of processes to minimize the impact of thermal deformation during production, users should still gain more knowledge in this area during regular use, follow standardized operating procedures, and reduce possible thermal deformation effects.

1. Reduce heat generation

The main source of thermal deformation arises from the internal heating of the machine. Heat sources should be separated from the main machine as much as possible.

2. Control temperature rise

After taking a series of measures to reduce heat sources, the situation of thermal deformation will improve. However, completely eliminating internal and external heat sources in the machine is usually very difficult, if not impossible. Therefore, it is necessary to control the temperature rise through effective cooling and heat dissipation to reduce the impact of heat sources. One effective method is to use forced cooling in the heating parts of the machine. Alternatively, heating the lower temperature parts of the machine can help make the temperature at all points of the machine more uniform, thereby reducing warping caused by temperature differences.

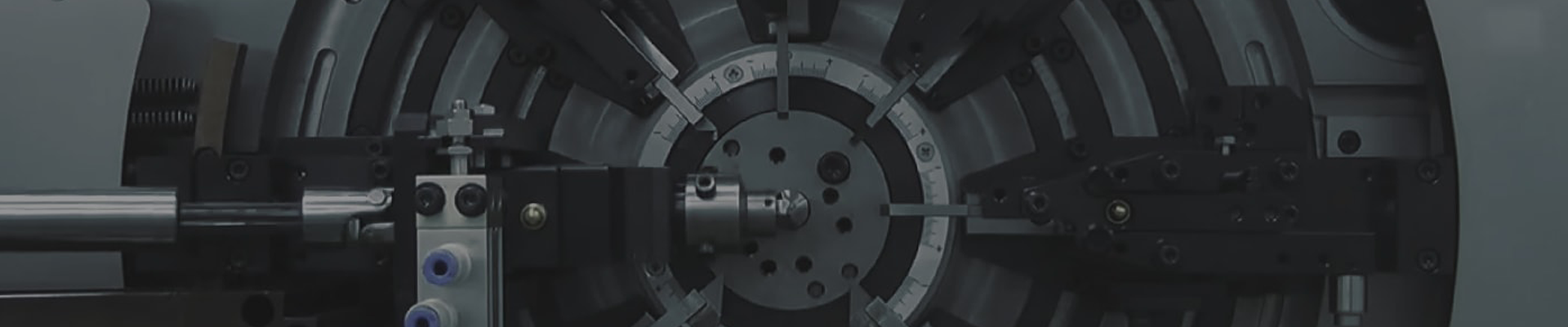

3. Improve machine structure

Under the same heating conditions, the machine structure also significantly affects thermal deformation. For example, in the past, CNC machines used single-column structures, which might be replaced by double-column structures. Due to left-right symmetry, with a double-column structure, the spindle line will primarily generate vertical translation when heated, while deformations in other directions are minimal. Furthermore, vertical axis movement can be easily compensated with a coordinate correction.

Thermal deformation of the spindle occurs in the direction perpendicular to the tool's cutting direction, which minimizes the impact of spindle thermal deformation on the processing diameter. Structurally, the distance between the spindle center and the ground should be minimized to reduce the total amount of thermal deformation, and the front and rear temperature rise of the spindle box should be consistent to prevent tilting after spindle deformation.

Ball screws in CNC machines often operate under conditions of high expected load, high speed, and poor heat dissipation, making them prone to heating. The consequences of heat generation in ball screws are serious, especially in open-loop systems, as it can cause the feed system to lose positioning accuracy. Currently, some machines use preloading to reduce thermal deformation of the screws. For thermal deformations that cannot be eliminated despite these measures, compensation pulses can be issued by the CNC system based on measurement results to correct them.